EPS sandwich panel thermal insulation

Packaging & Delivery

Specifications

EPS sandwich panel thermal insulation

Energy saving Environment friendly

Light Weight Area saving

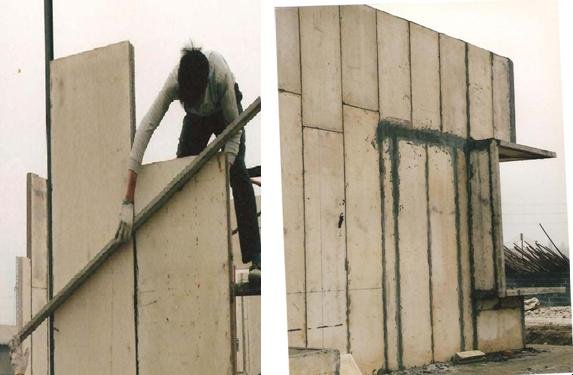

High efficient construction

Energy saving Environment friendly

Light Weight Area saving

High efficient construction

EPS sandwich panel thermal insulation

A kind of light weight energy saving compound board material taking fibre reinforced calcium silicon board or

cement calcium silicon board as panel,with cement,EPS,fly ash as fillers and forming by one time compound

Composition:

Core materials:cement,EPS,and fly ash core.

Surface materials:fiber reinforced calcium silicone board or cement calcium silicone board

Specification:(L*W*T)

1500 3000mmX610mmX(60,90,120,150,180mm)

Wall thickness:60,75,90,100,120,150 and 180mm

Maximum width:610mm

Length:according to custom demands,engineering requirements,and shipment conditions

Core materials:cement,EPS,and fly ash core.

Surface materials:fiber reinforced calcium silicone board or cement calcium silicone board

Specification:(L*W*T)

1500 3000mmX610mmX(60,90,120,150,180mm)

Wall thickness:60,75,90,100,120,150 and 180mm

Maximum width:610mm

Length:according to custom demands,engineering requirements,and shipment conditions

Product Feature

1)Energy-saving,Light weight,Environmental Protection

2)Most area-saving

3)Most Waterproof and Damp proof

4)Most Fire-proof

5)Most sound-insulation

6)Best Hanging Strength

7)Acid-resistant,alkali-resistant,rot-resistant

2)Most area-saving

3)Most Waterproof and Damp proof

4)Most Fire-proof

5)Most sound-insulation

6)Best Hanging Strength

7)Acid-resistant,alkali-resistant,rot-resistant

8)Most anti-seismic and impact resistance

9)Largest Span and height thin webbed wall

10)Most civilized,environmental,high efficient construction

9)Largest Span and height thin webbed wall

10)Most civilized,environmental,high efficient construction

Application

Interior and exterior partition on steel or concrete structure building

For new construction,additions or renovations.

Can replace construction materials as red bricks,clay solid bricks,air bricks,color coated steel sandwich boards,

For new construction,additions or renovations.

Can replace construction materials as red bricks,clay solid bricks,air bricks,color coated steel sandwich boards,

gypsum blocks,wire spatial grid structure perlite boards,and perlite porous board

Can widely be applied to wall materials of various high and low buildings such as

Can widely be applied to wall materials of various high and low buildings such as

banks,office buildings,hospitals,schools,hotels,malls,amusement halls,

active barracks,old houses reconstruction,residences,and workshops

Technology Index:

Supplied to: Iran, Russia, Australia, India, Dubai, South Africa Brazil and so on.

No comments:

Post a Comment