PVC/NBR rubber foam insulation

Packaging & Delivery

Specifications

1.Rubber foam insulation(free sample)

2.Largest manufacture and exporter in China

3.Competitive price

4.excellent quality

2.Largest manufacture and exporter in China

3.Competitive price

4.excellent quality

1.Low Conductivity Factor

Shenzhou rubber plastic has low thermal conductivity factor, which can be 0.034w/mk when the average temperature

is 0°C, and high surface heat emission coefficient that is up to 9.5w/M2k, therefore, in the same ambient conditions,

the application thickness is reduced by more than a half compared with other thermal insulating materials,

which saves the space above the suspended ceilings and increases the available space of every floor

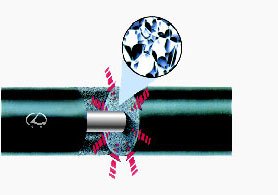

2.Extremely low water/damp penetration rate

Shenzhou rubber plastic has a closed foam structure and smooth surface, so water vapor in the air can hardly

penetrate the material. For this reason, no vapor insulating layer is needed, ensuring the best heat conduction effect.

With a moisture resistance factor more than 4.5×103, the products act as both a thermal insulating and a dampproof

layer

3.Good flame retardant performance and excenllent aging resistance

The product has excellent fire-resistance performance, and is verified to be fire retardant material at GB/8624 level B1

according to GB/8624-1997 Classification on Burning Behavior for Building Materials.

Shenzhou rubber plastic contains plenty of fire-resistance and smoke-reducing materials. When the material

Shenzhou rubber plastic contains plenty of fire-resistance and smoke-reducing materials. When the material

is burning, it will produce an extremely low density of smoke, and will not melt or drop any fire ball and can quench

by itself.

Various kinds of effective age resisting agents are added in Shenzhou rubber plastic during production, ensuring long

Various kinds of effective age resisting agents are added in Shenzhou rubber plastic during production, ensuring long

service life of the product.

4.Environmentally-friendly

The production process of Shenzhou rubber plastic generates no exhaust gas, waste water, scrap, smoke, fire or

other pollutants, and completely satisfies the requirements of ISO14000 international environment protection certification.

The product contains no chlorine or fiber and has good chemical stability, so it is safe free from releasing harmful

substances during installation and usage.

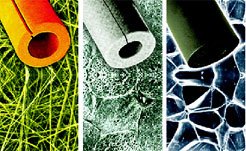

5.Comparison of performances between rubber plastic foamed thermal insulation material and other thermal

insulation materials

Fibrous thermal insulating materials have open apertures, so the vapor penetrating rate is extremely high. As the

using time of the material increases, its heat conductivity factor will grow, and the thermal insulating performance

will decrease greatly. In order to prevent condensation, a vapor resistance layer must be added. However, valves

and some other special parts are hard to be treated, and condensation may happen to them, which will cause failure

of the whole thermal insulating system.

Both the production and usage of fibrous thermal insulating materials are harmful to the environment and human

Both the production and usage of fibrous thermal insulating materials are harmful to the environment and human

bodies to some extent.

Polystyrene and PEF thermal insulating materials have low oxygen indexes, poor fire resistance performance,

Polystyrene and PEF thermal insulating materials have low oxygen indexes, poor fire resistance performance,

fragile texture and short service life.

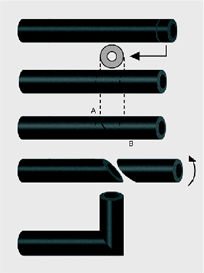

6.Easy and quick installation

Shenzhou rubber plastic is flexible and easy to be installed. In the installation of pipelines, according to the actual need

of schedule, you may choose to enclose the pipes in the rubber plastic covers, or cut the covers first and stick them

together after wrapping the pipes with special adhesive before installing the pipelines. For valves, elbows, tee-junctions,

etc. that are in complex shapes, you may first cut the sheet material and pipe covers according to actual demand,

choose the right types of materials for the different shapes to wrap, and then glue the materials. In this way, the air

impermeability of the whole system is guaranteed while the appearance is good-looking.

7.Basic operating rules

We suggest you to use “Green City” glue and adhesive tape for rubber plastic, also the products of us.

All the cuts and joints must be stuck and sealed with glue.

Prior to sticking up the materials, check the sizes of the pipes first, and then stick them in from-large-to-small sequence,

All the cuts and joints must be stuck and sealed with glue.

Prior to sticking up the materials, check the sizes of the pipes first, and then stick them in from-large-to-small sequence,

i.e., elbows, tee-junctions, pipes, valves and flanges.

The glue should be applied in proper amount, and the stuck joints should be slightly pressed.

If superposed thermal insulation is required for large-thickness insulating application, the cuts of every layer should

The glue should be applied in proper amount, and the stuck joints should be slightly pressed.

If superposed thermal insulation is required for large-thickness insulating application, the cuts of every layer should

be staggered.

The material must not be stretched in installation, and a margin of 10mm should be reserved.

The material must not be stretched in installation, and a margin of 10mm should be reserved.

No comments:

Post a Comment